A predictive model, utilizing State-of-the-art machine Mastering methods with multi-aspect multi-design ensemble and dynamic smoothing plan, is formulated. The applicability of the framework is always that it will require into account machining parameters, such as depth of Slash, cutting speed and feed charge, as inputs into the product, Consequently creating The true secret characteristics for that predictions. Actual info with the machining experiments were collected, investigated and analysed, with prediction effects displaying high agreement with the experiments with regards to the traits on the predictions as well as the precision with the averaged root mean squared mistake values.

By integrating AI to make programming and toolpath definition more efficient, manufacturers can capitalize on awareness, streamlining operations and maximizing productivity.

The processing precision of CNC lathes can achieve ±0.01mm, as well as processing efficiency is over thirty% greater than that of traditional machine tools. It really is an indispensable and crucial equipment in modern manufacturing and it is broadly used in industries like vehicles, aviation, healthcare equipment and mould production.

The integration of AI while in the CNC industry is just not an optional upgrade, but a requirement for competitiveness from the quickly evolving electronic environment. From operational efficiency to cost cost savings and enhanced performance, AI is reshaping the confront of CNC production, providing benefit at every stage.

Learn how AI and CNC machines are reworking production. Discover the seven key tendencies that should impression your machine shop’s productivity, profitability, and competitiveness in 2025 and further than.

The development from the FANN came about in three phases, in Each and every section the neural networks fashioned had been trained by drilling lengths until finally the drill little bit was worn out and by a variable parameter, although the combinations of another influencing parameters had been taken as continual values. The final results of the prediction acquired by implementing the FANN were being when compared with the outcome acquired by regression Assessment within the details of experimental benefits. The comparison confirmed that the FANN could be used as an exceptionally reliable technique for predicting tool condition.

On earth of manufacturing, CNC machining is popping out on top rated. CNC machining is used just about everywhere within the automotive and health-related industries to aerospace, gasoline and oil, and warehouse operations.

Predicting servicing by receiving in front of a potential concern is essential to growing machine uptime and Total Equipment Usefulness (OEE). Good usage of AI in production means clever decision-earning by you.

Cutting Process: The Software cuts, drills, or grinds the fabric to form the workpiece into the desired type.

Machine Understanding algorithms, by continual Assessment of operational knowledge, can enhance machine operations. Irrespective of whether it’s adjusting the spindle pace or optimizing Resource paths, ML makes sure that the machine operates at peak efficiency, lessening waste and improving upon product or service quality.

With these innovative tools, manufacturers can now craft complex components that meet up with even the very best criteria of precision.

As impressive as machines are, human CNC machine operators are essential to the procedure, especially good quality control. What AI presents is actually a center on analytics and genuine-time info, Mastering together the way in which and delivering insights so CNC machine operators can improve the machine’s performance.

State-of-the-art machine Discovering algorithms are now earning sizeable strides in optimizing CNC procedures. Reinforcement Finding out is an additional location of machine Understanding to look at, exactly where machines learn how to behave by observing the effects of executed actions.

Woodworking: Woodworkers count on modern CNC machines to quickly, properly and precisely craft a wide array of wood objects. From cupboard creating and home furniture setting up jobs to building check here intricate carvings or comprehensive engravings, MultiCam CNC would be the drop by technology for these industries.

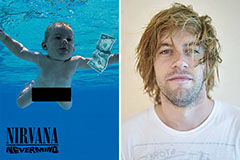

Spencer Elden Then & Now!

Spencer Elden Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now!