As a result of not enough deviations in precision machining, you can find much less defective productions. So the method leads to a lessen rejection amount of parts. Consequently, the price of materials is reduce.

Besides these milling operations we will use the milling machine for the next functions in addition.

Due to the ability degree needed to make precision machined parts, numerous organizations will outsource their precision machining Positions even if they've CNC machining equipment of their unique.

Although some plastic parts is usually crafted with injection molding, metal parts, and any complex parts completely use CNC machining. A few of the parts that healthcare manufacturers craft with CNC machines are:

Hand-drawn sketches are generally used to comprehend the core ideas of a component. The CAD designer then resorts to these sketches to generate the graphical product with precise measurements.

In considering the fact that-eliminated enterprise webpages, Bredikhin described his company like a “Russian branch” of I Machine Tools. The outline is among several indicators that the companies are related.

Precision machining entails higher-velocity robotics that may develop parts a lot quicker than handbook manufacturing on standard lathes.

It's really a subtractive manufacturing procedure the place the machine starts with a block and removes content from it with a cutting tool. Precision machining is often used for making an assortment of parts that fit and work collectively.

In CNC machines there ought to have the components, program application, and studies to accomplish the machining functions. the principal hardware is Microprocessor and so one can regulate perform and peripheral interaction between gadgets.

Carbon Fiber—Composites and Glass Fibre can the two be machined for applications that need light-weight however sturdy Qualities, such as aerospace and sporting merchandise manufacturing.

In addition, currently being an automated Laptop-aided manufacturing course of action brings about minimized labor prices. The put together reduction in labor charges and content charges implies that the production fees of CNC machining are reduced than any choices.

CNC machining would be the go-to system for making jewellery and etching and engraving. Jewellery-making utilizes CNC milling machines, CNC lathes, CNC routers, and CNC laser engraving machines. A jewellery CNC machine not merely allows manufacture and type metal jewellery but will also in grinding and sprucing things.

High quality Inspection: The moment CNC check here parts happen to be machined, they undertake an in-depth excellent inspection process to be certain each one satisfies design specs and tolerances. With significant-precision CNC machines available today, achieving constant high-quality across large production batches is possible.

As we strategy the 2030s, the die and mildew industry will reap the benefits of even further developments in multi-axis machining and substantial-pace CNC technology.

Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Melissa Sue Anderson Then & Now!

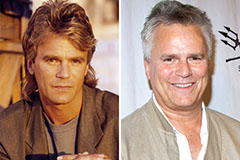

Melissa Sue Anderson Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!